Overview of the Plant-Based Proteins Market| 2024 - 2031

Meticulous Research®, a leading global market research firm, has published an insightful report titled “Plant-based Proteins Market By Type (Soy Proteins, Wheat Proteins, Pea Proteins, Potato Proteins), Form (Solid, Liquid), Source Process (Conventional, Organic), and Application (Food and Beverages, Animal Read More..

Additional resources

- Jeux Casino En Ligne

- Meilleur Casino En Ligne

- Meilleur Casino En Ligne

- Meilleur Casino En Ligne

- Sites De Paris Sportifs En Belgique

- Site Paris Sportif Belgique

- Paris Sportifs Belgique

- Meilleur Casino En Ligne Belgique

- Meilleur Site Casino En Ligne Belgique

- Migliori Casino Online

- Casino Online App

- Siti Scommesse Bitcoin

- Site De Paris Sportif Bonus

- Sweet Bonanza Avis

- Ufc Paris Sportif

- オンカジ 出金 早い

- 本人確認不要 カジノ

- онлайн казино зарубежные

- Nhà Cái đến Từ Châu âu

- Site Paris Sportif Retrait Instantané

- Site De Paris Sportifs

- Nouveau Casino En Ligne Francais

- Casino En Ligne

- Nouveau Casino En Ligne Fiable

- Casino En Ligne 2026

- Casino Senza Richiesta Documenti

- Casino En Ligne Qui Paye Vraiment

- Casino En Ligne Fiable

- Casino Bitcoin

- Casino Italiani Non Aams

- Migliori Casino Online Italia

- Siti Non Aams Sicuri

- Casino Non Aams

- Meilleur Site De Casino En Ligne Belgique

- オンラインカジノ

- Meilleur Casino En Ligne France

- Casino En Ligne France

- Casino En Ligne Qui Paye Rapidement

- Casino En Ligne 2026

Oncology Information Systems Market to be Worth $4.45 Billion by 2030

Introduction

Meticulous Research® recently released a comprehensive report titled “Oncology Information Systems Market By Offering (Software, Services) Application (Medical, Surgical, Radiology Oncology) End User (Hospital, Diagnostic Imaging Center, Cancer Care Center) - Global Forecast to 2030.” The report reveals that Read More..

Summary of Meticulous Research® Report on RWE Oncology Market

Meticulous Research®, a leading global market research firm, has released a comprehensive report titled, “RWE Oncology Market by Component (Datasets [EHR, Claims, Cancer Registries], Consulting & Analytics Services), Application (Drug Development, Approval, Market Access, Post-market Surveillance), End User (Pharma, Payer, Read More..

Analysis of the Real-World Evidence Solutions Market| Trends and Key players

Meticulous Research®, a prominent global market research firm, has released a detailed report titled “Real-world Evidence Solutions Market Size, Share, Forecast, & Trends Analysis by Component (Datasets, Services), Application (Market Access, Drug Development & Approvals, Post-Market Surveillance), and End User Read More..

Botanicals Market: Growth Analysis, Key Trends, and Future Prospects for 2024

The Botanicals Market was valued at $12.58 billion in 2023. This market is expected to reach $24.97 billion by 2031 from an estimated $13.69 billion in 2024, at a CAGR of 9% during the forecast period from 2024 to 2031.

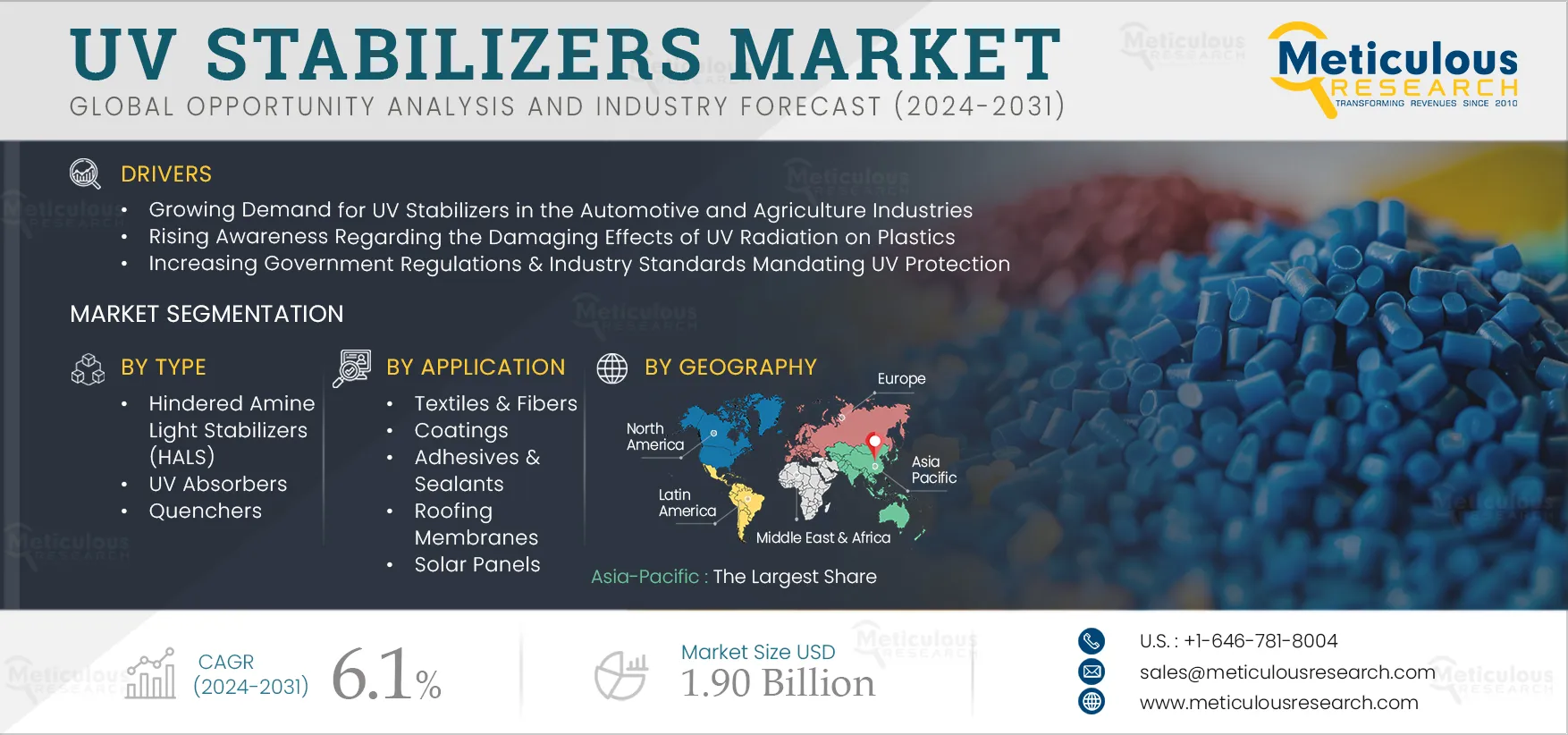

Read More..UV Stabilizers Market: In-Depth Analysis of Trends, Insights, and Future Growth Forecast (2024–2031)

As global industries prioritize sustainability and durability, UV stabilizers have become essential to combat ultraviolet (UV) radiation damage in materials. From automotive and agriculture to construction and packaging, the need for robust UV protection has spurred significant advancements in the Read More..