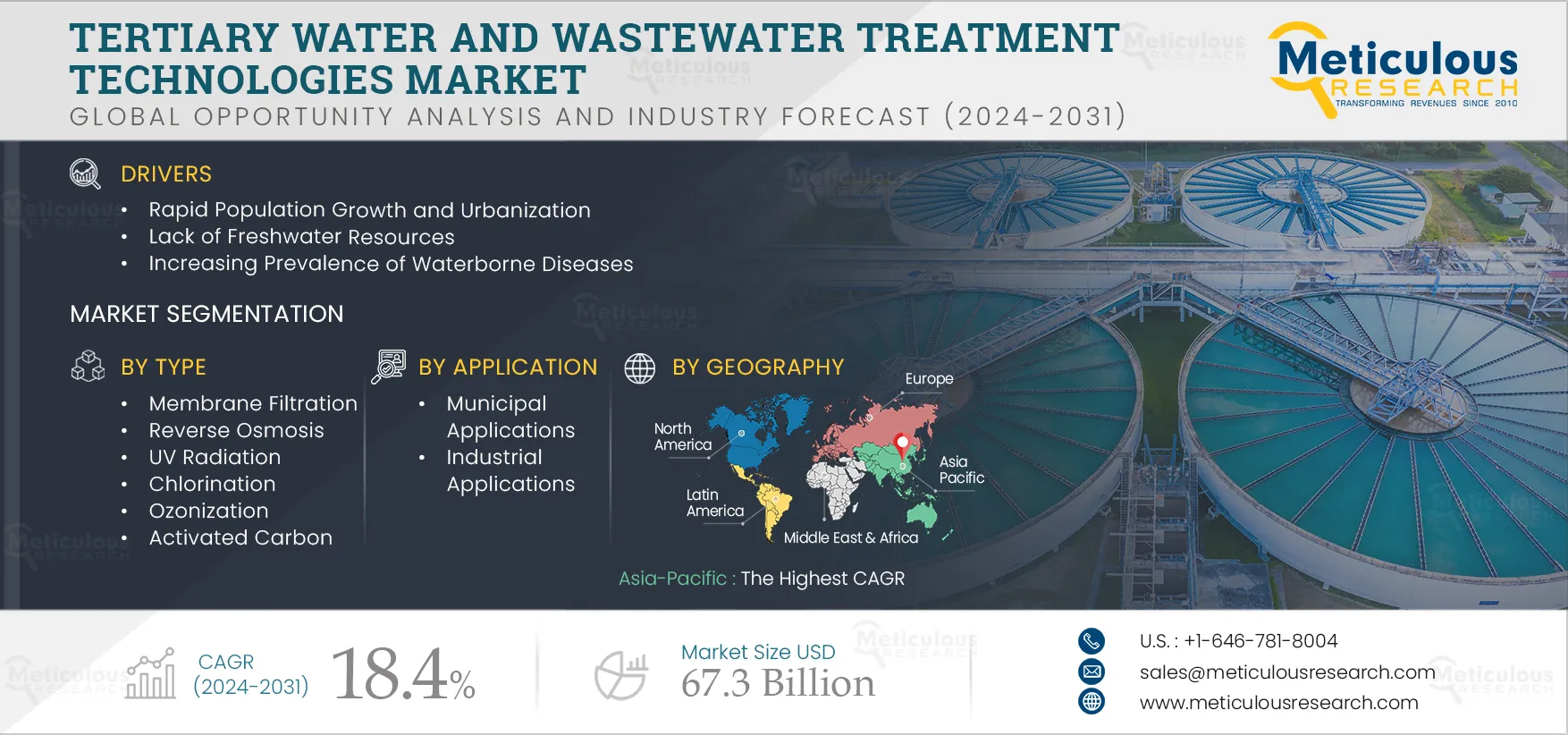

The Tertiary Water and Wastewater Treatment Technologies Market is projected to reach $67.3 billion by 2031, at a CAGR of 18.4% from 2024 to 2031.

Freshwater scarcity has emerged as one of the most pressing global challenges of the 21st century, posing severe threats to economic stability, water security, and environmental health. With rising population growth, rapid industrialization, and the exacerbating effects of climate change, the pressure on freshwater resources has escalated to critical levels. Access to adequate and safe drinking water is becoming increasingly complex, especially as the demand continues to grow across public, industrial, and agricultural sectors. One of the most concerning factors contributing to this issue is the extensive consumption of freshwater, paired with the vast quantities of wastewater generated by industries and municipalities. If not properly managed, wastewater discharge can lead to severe environmental pollution, harming aquatic ecosystems and threatening public health.

In response to these challenges, there has been a marked shift towards innovative and sustainable water management practices, particularly the recovery and reuse of wastewater. Over the past decade, this approach has gained significant momentum as a solution to minimize freshwater withdrawal and reduce environmental risks. By recovering and recycling wastewater, industries can not only reduce the volume of waste but also enhance water usage efficiency. One technology at the forefront of this movement is Zero Liquid Discharge (ZLD).

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=5185

What is Zero Liquid Discharge (ZLD)?

Zero Liquid Discharge (ZLD) is an advanced water treatment process that aims to eliminate liquid waste from industrial systems, allowing for the complete reuse of treated water. ZLD technology ensures that no liquid waste is released into the environment, thereby mitigating the pollution risks associated with wastewater discharge. It provides a holistic solution for industries seeking to enhance water efficiency and adhere to stringent environmental regulations.

At its core, ZLD integrates various advanced treatment technologies to purify wastewater and recover clean water that can be reused within the system. By doing so, ZLD not only addresses the challenge of wastewater management but also promotes resource conservation. The solids that are left behind after the liquid has been extracted can often be recovered and reused, providing additional economic benefits to industries.

Key Drivers of ZLD Adoption

The adoption of ZLD technology is being propelled by several key factors, all of which are becoming increasingly relevant as the global water crisis intensifies. These include:

- Stringent Environmental Regulations: Governments and environmental agencies around the world are imposing stricter regulations on wastewater discharge and water reuse. Agencies such as the U.S. Environmental Protection Agency (EPA), the European Water Association, and the India Water Works Association have introduced robust policies that require industries to adopt sustainable wastewater management practices. In certain regions, ZLD is becoming a mandated solution, especially in water-stressed countries like China and India.

- Water Scarcity: As freshwater resources become more scarce, industries are being forced to explore alternative sources of water to meet their operational needs. ZLD provides an effective means of recycling wastewater, thus reducing the dependency on external freshwater supplies. In water-scarce regions, ZLD is increasingly viewed as a necessity for sustainable industrial operations.

- Cost Considerations: While the initial investment in ZLD technology can be substantial, the long-term economic benefits can outweigh the costs. By recovering and reusing water, industries can significantly reduce their water acquisition costs. Additionally, ZLD helps lower waste disposal expenses, as it eliminates the need for off-site wastewater treatment and disposal.

- Resource Recovery: ZLD systems offer the potential to recover valuable resources from wastewater, such as salts, minerals, and other by-products that can be repurposed or sold. For example, ammonium sulfate extracted from wastewater can be used as a fertilizer, while sodium chloride can be utilized for ice melting. This resource recovery aspect adds an additional layer of value to ZLD systems, making them more attractive to industries looking to optimize both environmental performance and economic efficiency.

The Role of ZLD in Industrial Wastewater Management

Industries are among the largest consumers of freshwater, and they generate significant volumes of wastewater during their operations. These waste streams often contain a variety of pollutants, including heavy metals, organic compounds, and salts, which can be harmful to the environment if not treated properly. ZLD technology plays a critical role in addressing the environmental impacts of industrial wastewater by ensuring that no liquid waste is discharged.

Several industrial sectors have already embraced ZLD as part of their wastewater management strategy. These include:

- Power Generation: The energy industry, particularly coal-fired power plants, is a major adopter of ZLD technology. Power plants require large volumes of water for cooling purposes, and the wastewater generated contains high concentrations of dissolved solids. ZLD helps these facilities recycle water and reduce their environmental footprint, in line with regulatory requirements.

- Chemicals and Pharmaceuticals: The chemical and pharmaceutical industries produce complex waste streams that can contain hazardous substances. ZLD systems are used to treat these waste streams, ensuring that harmful contaminants are removed, and the treated water can be reused within the facility.

- Textile and Dyeing: Textile production is one of the most water-intensive industries, with significant wastewater generation during the dyeing and finishing processes. ZLD technology enables textile manufacturers to recycle water and minimize their environmental impact, particularly in regions where water is scarce.

- Food and Beverage: The food and beverage industry also relies heavily on water for production processes. ZLD can help these facilities reduce their water usage by recycling wastewater and recovering valuable by-products, such as organic compounds that can be repurposed.

Benefits of Implementing ZLD Systems

The benefits of ZLD technology extend beyond just environmental protection. Industries that implement ZLD systems can achieve several advantages, including:

- Reduced Environmental Impact: By preventing the discharge of liquid waste, ZLD eliminates the risk of water pollution and helps preserve aquatic ecosystems. This is particularly important in areas where water bodies are already under stress from industrial activities.

- Compliance with Regulations: As environmental regulations become more stringent, ZLD helps industries meet compliance requirements, thereby reducing the risk of fines, penalties, or operational shutdowns. It also improves the company’s reputation as a responsible corporate citizen.

- Cost Savings: Recycling water on-site reduces the need for purchasing freshwater, leading to significant cost savings. Additionally, by minimizing waste disposal volumes, ZLD lowers the costs associated with off-site waste management and transportation.

- Resource Recovery: ZLD systems offer the added benefit of recovering valuable resources from wastewater, which can be reused within the industrial process or sold to generate additional revenue.

- Operational Efficiency: ZLD technology enhances the overall efficiency of industrial operations by optimizing water usage and reducing the dependency on external water sources. This is particularly beneficial in water-scarce regions where securing a reliable supply of freshwater can be challenging.

Get Insightful Data On Regions, Market Segments, Customer Landscape, And Top Companies (Charts, Tables, Figures And More) :- https://www.meticulousresearch.com/request-sample-report/cp_id=5185

Technological Advancements in ZLD Systems

Over the years, advancements in ZLD technology have made it more accessible and efficient for a wider range of industries. Several key innovations are driving the growth of ZLD systems:

- Membrane Technologies: Membrane-based technologies, such as reverse osmosis (RO) and nanofiltration, are commonly used in ZLD systems to concentrate wastewater before the final stage of evaporation. These technologies offer high efficiency in separating contaminants from water and are increasingly being integrated into ZLD processes.

- Evaporation and Crystallization: Evaporation is a critical component of ZLD systems, as it allows for the removal of water from the waste stream, leaving behind concentrated solids. Crystallization processes can then be used to recover these solids for reuse or disposal. Advances in evaporator design have improved the energy efficiency of these systems, making them more cost-effective.

- Hybrid Systems: Many ZLD systems now incorporate a combination of treatment technologies to achieve optimal results. Hybrid systems that integrate membrane filtration, biological treatment, and thermal processes are becoming more popular due to their ability to handle a wider range of waste streams and achieve higher water recovery rates.

ZLD in Global Markets

The global market for ZLD technology is experiencing rapid growth, driven by increasing demand for water conservation and stricter environmental regulations. According to a report by Meticulous Research®, the global ZLD market is projected to grow at a compound annual growth rate (CAGR) of 7.2% over the next several years, reaching a market value of USD 35.5 billion by 2027.

This growth is being fueled by the adoption of ZLD systems in regions such as Asia-Pacific, where water scarcity is a major concern. In countries like China and India, government initiatives aimed at improving water management are driving the implementation of ZLD technology across various industrial sectors. For example, China’s 12th Five-Year Plan mandates the use of ZLD in new and existing coal-fired power plants, while India has introduced ZLD requirements for industries such as pharmaceuticals, textiles, and chemicals.

The Future of ZLD Technology

As industries continue to grapple with the challenges of water scarcity and environmental regulations, ZLD technology is poised to play an increasingly important role in wastewater management. Innovations in treatment processes, coupled with growing awareness of the need for sustainable water practices, will drive the continued expansion of ZLD systems.

Industries that invest in ZLD technology today stand to benefit from improved water efficiency, reduced environmental impact, and enhanced regulatory compliance. As the global demand for water resources intensifies, ZLD will remain a critical tool for industries seeking to balance operational efficiency with environmental stewardship.

Immediate Delivery Available | BUY THIS RESEARCH REPORT (Insights, Charts, Tables, Figures and More) – https://meticulousresearch.com/Checkout/29290315

Segment Covered

By Type

- Membrane Filtration

- Reverse Osmosis

- UV Radiation

- Chlorination

- Ozonization

- Activated Carbon

- lon Exchange

- Electrochemical Water Treatment Technology

- Other Tertiary Treatment Technologies

By Application

- Municipal Applications

- Industrial Applications

- Manufacturing

- Pharmaceuticals and Chemicals

- Power

- Energy

- Pulp and Paper

- Mining

- Petrochemicals

- Semiconductors

- Other Industrial Applications

Contact:

Meticulous Market Research Pvt. Ltd.

1267 Willis St, Ste 200 Redding,California, 96001, U.S.

USA: +1-646-781-8004

Europe: +44-203-868-8738

APAC: +91 744-7780008

Email– sales@meticulousresearch.com

Visit Our Website: https://www.meticulousresearch.com/

Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research