The Machine Condition Monitoring Market is expected to reach $5.2 billion by 2029, at a CAGR of 7.3% during the forecast period 2022–2029.

In today’s rapidly evolving landscape, enterprises across various industries are increasingly adopting cutting-edge technologies to boost operational efficiency and reduce costs. The consistent growth of industrial automation is paving the way for a range of auxiliary technologies to gain traction in the manufacturing sector. These advancements not only improve production processes but also enable businesses to adapt to changing market demands.

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=5328

The Role of IoT in Industrial Automation

One of the most significant trends in industrial automation is the integration of Internet of Things (IoT) sensors for machine condition monitoring. This technology has revolutionized predictive maintenance, allowing for real-time monitoring of equipment and machinery. By leveraging IoT sensors, manufacturers can detect potential issues before they escalate, thereby minimizing downtime and extending the life of their assets.

Key market players are actively launching sensor-enabled predictive maintenance solutions to cater to the industrial sector’s needs. For instance, in 2022, Sensata Technologies, Inc. (U.S.) introduced a groundbreaking asset monitoring solution designed for the predictive maintenance of rotary assets. This innovative wireless industrial IoT sensor empowers plant managers to identify early-stage faults and derive actionable insights, significantly enhancing operational efficiency.

Enhancements in Flow Control

Similarly, in 2021, Flowserve Corporation (U.S.) unveiled a new IoT service suite called RedRaven, tailored to support flow control equipment. This suite comprises sensors that collect valuable data from assets, transmitting it to the cloud using a secure, data-encrypted solution. By harnessing this technology, manufacturers can optimize the performance of their flow control systems, improving reliability and reducing operational risks.

Get Insightful Data On Regions, Market Segments, Customer Landscape, And Top Companies (Charts, Tables, Figures And More) :- https://www.meticulousresearch.com/request-sample-report/cp_id=5328

Industrial Analytics: Driving Data-Driven Decisions

In addition to IoT, another crucial automation technology making waves in the industrial sector is Industrial Analytics (IA). This technology focuses on collecting, analyzing, and utilizing data generated from industrial operations throughout the entire product lifecycle. By implementing modern data capture methods and advanced analytic modeling, manufacturers can extract meaningful insights from their operations.

As industrial assets become increasingly digitized through the integration of sensors and the Industrial Internet of Things (IIoT), manufacturers can analyze machine data to improve production efficiency, reduce downtime, cut costs, and enable better decision-making. For instance, advanced analytics software powered by artificial intelligence (AI) and machine learning (ML) can facilitate intelligent operations in various areas, such as predictive maintenance, real-time quality control, and scenario testing for root cause analysis.

The Impact of AI and Machine Learning

The incorporation of AI and ML into industrial analytics allows for more sophisticated data analysis, enabling predictive capabilities that were previously unattainable. These technologies can identify patterns and anomalies within vast datasets, providing insights that help organizations anticipate equipment failures and optimize maintenance schedules. As a result, manufacturers can enhance productivity and ensure a smoother workflow, ultimately contributing to improved profitability.

Government Initiatives Supporting Industrial Automation

The growth of industrial automation is further bolstered by local governments’ consistent efforts to promote programs such as Industry 4.0. These initiatives aim to modernize the manufacturing landscape, encouraging the adoption of advanced technologies and automation processes.

Singapore: A Leader in Automation

Singapore has emerged as a leading adopter of automation in Southeast Asia, thanks to various government-backed initiatives, including the National Robotics Program. In 2019, Singapore witnessed the rollout of the Narrowband IoT (NB-IoT) network, a connectivity standard supported by telecommunications companies and the GSM Association. This development has accelerated the progress of Singapore’s digital economy and manufacturing sector, facilitating the integration of IoT technologies in industrial processes.

The government’s commitment to fostering innovation and technological advancement has created a conducive environment for businesses to explore automation opportunities. With a robust infrastructure and strategic initiatives, Singapore aims to position itself as a regional hub for advanced manufacturing and industrial automation.

Malaysia’s National Industry 4.0 Framework

In a similar vein, Malaysia has proposed the National Industry 4.0 Framework to enhance its manufacturing sector. This framework aims to elevate the country’s industrial landscape by promoting the adoption of Industry 4.0 technologies, including automation, data analytics, and IoT solutions. By fostering collaboration between government agencies, industry stakeholders, and educational institutions, Malaysia seeks to create a skilled workforce capable of driving technological innovation.

Such initiatives are crucial for promoting industrial automation and expanding opportunities for technologies like machine condition monitoring to thrive. As countries prioritize technological advancement, the potential for growth in the industrial automation sector continues to rise.

Scope of the Report:

Machine Condition Monitoring Market, by Component

- Hardware

- Sensors

- Analyzers

- Other Hardware

- Software

- Services

Machine Condition Monitoring Market, by Deployment Mode

- On-premise deployment

- Cloud-based deployment

Machine Condition Monitoring Market, by Monitoring Process

- Online Monitoring

- Portable Monitoring

Machine Condition Monitoring Market, by Monitoring Technique

- Vibration Monitoring

- Corrosion Monitoring

- Thermography

- Oil Analysis

- Ultrasound Monitoring

- Other Monitoring Techniques

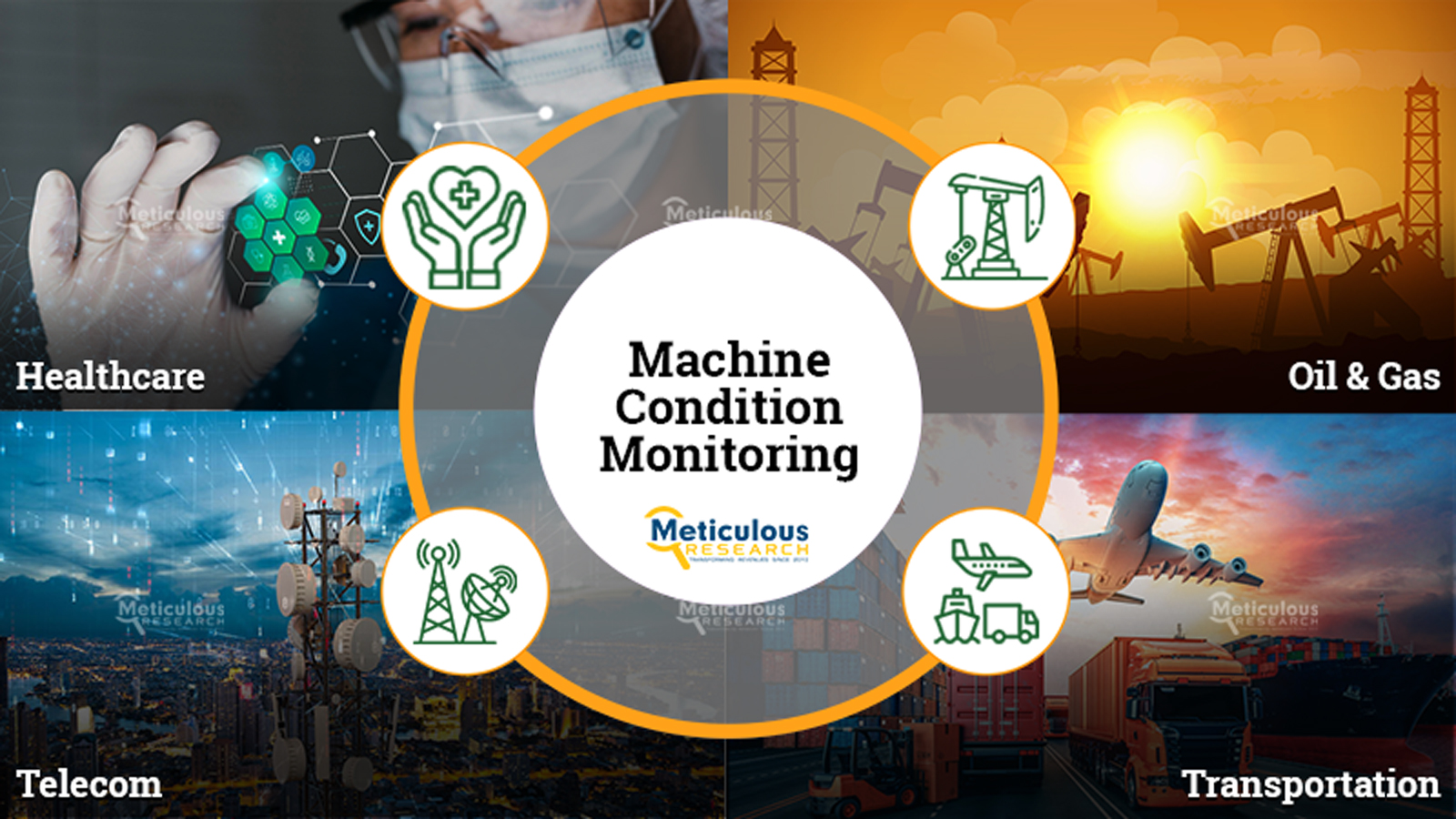

Machine Condition Monitoring Market, by End-use Industry

- Manufacturing

- Healthcare

- Energy & Utilities

- Aerospace

- Telecom

- Agriculture

- Oil & Gas

- Transportation & Logistics

- Other End-use Industries

Challenges in Adopting Advanced Automation Technologies

Despite the promising advancements in industrial automation, several challenges persist. One significant hurdle is the integration of new technologies into existing manufacturing processes. Many organizations still rely on legacy systems that may not be compatible with the latest advancements, complicating the transition to automated solutions.

Moreover, the need for a skilled workforce capable of operating and maintaining advanced technologies is paramount. As automation becomes more prevalent, companies must invest in training and development programs to ensure their employees are equipped with the necessary skills to navigate this new landscape.

Security Concerns in Industrial Automation

Another pressing concern is the security of connected devices and networks. As industrial operations become increasingly digitized, the risk of cyber threats rises. Manufacturers must prioritize cybersecurity measures to protect their assets and sensitive data from potential breaches.

Immediate Delivery Available | BUY THIS RESEARCH REPORT (Insights, Charts, Tables, Figures and More) – https://www.meticulousresearch.com/Checkout/54480657

The Future of Industrial Automation

Looking ahead, the future of industrial automation appears promising. The increasing demand for efficiency, cost reduction, and improved operational performance will drive further investments in advanced technologies. As industries continue to evolve, manufacturers must embrace digital transformation to remain competitive in a rapidly changing landscape.

The integration of IoT, industrial analytics, AI, and machine learning will play a pivotal role in shaping the future of industrial automation. By leveraging these technologies, organizations can optimize their operations, enhance decision-making, and achieve sustainable growth.

Contact Us:

Meticulous Market Research Pvt. Ltd.

1267 Willis St, Ste 200 Redding,California, 96001, U.S.

USA: +1-646-781-8004

Europe: +44-203-868-8738

APAC: +91 744-7780008

Email– sales@meticulousresearch.com

Visit Our Website: https://www.meticulousresearch.com/

Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

Meticulousblog.org | Top Market Research Reports Blog – https://meticulousblog.org/