The Thermoelectric Modules Market is projected to reach $1.46 billion by 2030, at a CAGR of 10.6% during the forecast period of 2023–2030.

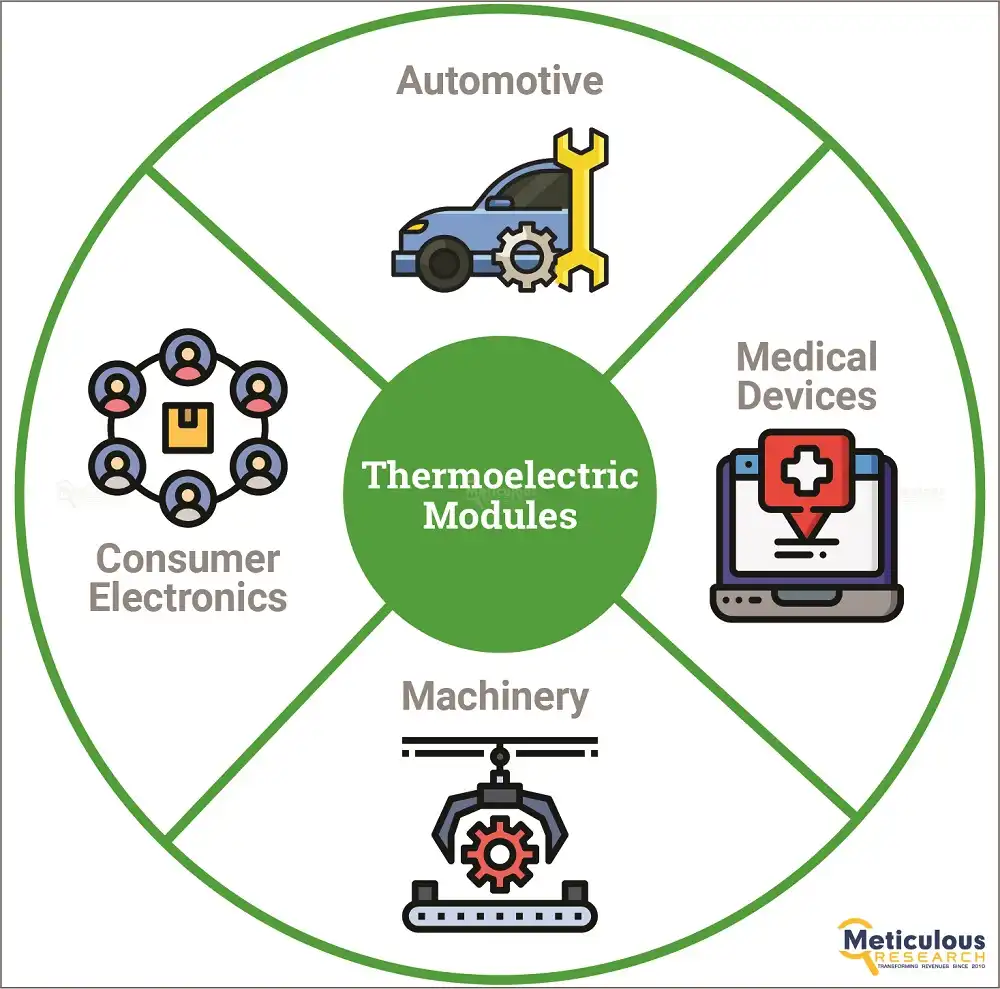

The increasing adoption of electric and luxury vehicles is anticipated to significantly boost the growth of the thermoelectric modules market. Luxury and ultra-luxury vehicles are known for offering superior comfort, advanced safety features, high-end driving performance, stylish designs, and an exclusive ownership experience. These features, including exceptional performance, aesthetics, exclusivity, and brand legacy, are expected to continue attracting affluent buyers in the coming years. Thermoelectric modules are widely used in luxury and ultra-luxury vehicles for functions such as automotive seat heating/cooling, cup holders, glove compartments, night vision, and waste heat recovery.

Download Complete Sample PDF Copy Here: https://www.meticulousresearch.com/download-sample-report/cp_id=5494

Additionally, rising greenhouse gas emissions and growing environmental concerns have led governments and environmental agencies worldwide to enforce stricter emission standards. This has accelerated the demand for sustainable and eco-friendly transportation options, such as electric vehicles (EVs). Many governments also offer incentives and subsidies to EV buyers, further driving the demand for these vehicles.

In 2022, global electric car sales surged by approximately 60%, surpassing 10 million units for the first time. Data from the International Energy Agency (IEA) shows that one in every seven passenger cars purchased globally in 2022 was electric. Thermoelectric modules are increasingly used in EVs to heat batteries and enhance their performance in cold weather conditions. Therefore, the growing demand for EVs is expected to stimulate the demand for thermoelectric modules.

Moreover, many electronic devices, including compact power electronics, LEDs, sensors, and central processing units (CPUs), require effective thermal control systems to ensure optimal performance and prevent overheating. The trend toward miniaturization and compactness in electronics has limited the available surface area for heat dissipation, making thermal management more challenging. Cooling systems have become critical for maintaining performance and preventing failures in these devices. Traditional cooling technologies like air cooling, liquid cooling, and heat pipes have been effective in managing heat but require external energy, which increases energy consumption and operating costs. As a result, thermoelectric cooling is gaining traction as a more efficient solution for managing the thermal needs of high-performance electronics.

Check complete table of contents with list of table and figures: https://www.meticulousresearch.com/product/thermoelectric-modules-market-5494

Thermoelectric cooling technology offers several advantages over conventional vapor-compression systems, including a more compact design, lower maintenance, reduced vibration, and quieter operation, making it suitable for noise-sensitive environments. Furthermore, TE cooling provides precise temperature control, which is crucial for cooling electronic components. These benefits have encouraged innovation and the development of new applications. For instance, in July 2021, Laird Thermal Systems, Inc. (U.S.) introduced the OptoTEC OTX/HTX Series of miniature thermoelectric coolers for high-temperature optoelectronics. Similarly, TEC Microsystems launched the 1MA10 Series of thermoelectric coolers with aluminum plates in 2020, replacing traditional ceramic plates.

However, the high production costs of thermoelectric modules compared to conventional heating/cooling systems present a major challenge for the market. While materials for high-temperature thermoelectric modules are widely available, the cost of system components, such as heat exchangers and ceramic plates, remains a barrier to cost-effective production. Consequently, high-temperature modules are generally too expensive for widespread commercial use, though they may still be viable in niche markets less sensitive to cost constraints. Additionally, most TE modules are manually assembled, requiring specialized welding materials and tools that can withstand high temperatures, adding to the cost.

Buy Now: https://www.meticulousresearch.com/Checkout/15046663

Companies in the thermoelectric modules market face further challenges related to ensuring reliability and durability, as well as managing the design complexities of these modules. The reliability of thermoelectric devices can vary significantly depending on the application. In steady-state cooling applications with consistent DC power, thermoelectric modules have a high reliability, with a Mean Time Between Failures (MTBF) often exceeding 200,000 hours, a widely accepted industry standard. However, reliability can decrease in thermal cycling applications, especially when modules are exposed to high temperatures. While thermoelectric modules exhibit strong mechanical performance under compression, their shear strength is relatively low. Despite these challenges, industry players are actively working to simplify the design and improve the overall performance and reliability of thermoelectric modules.

Contact Us:

Meticulous Market Research Pvt. Ltd.

1267 Willis St, Ste 200 Redding,

California, 96001, U.S.

USA: +1-646-781-8004

Europe : +44-203-868-8738

APAC: +91 744-7780008

Email- [email protected]

Visit Our Website: https://www.meticulousresearch.com/

Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

About Post Author

Meticulous Research

Additional resources

- Jeux Casino En Ligne

- Meilleur Casino En Ligne

- Meilleur Casino En Ligne

- Meilleur Casino En Ligne

- Sites De Paris Sportifs En Belgique

- Site Paris Sportif Belgique

- Paris Sportifs Belgique

- Meilleur Casino En Ligne Belgique

- Meilleur Site Casino En Ligne Belgique

- Migliori Casino Online

- Casino Online App

- Siti Scommesse Bitcoin

- Site De Paris Sportif Bonus

- Sweet Bonanza Avis

- Ufc Paris Sportif

- オンカジ 出金 早い

- 本人確認不要 カジノ

- онлайн казино зарубежные

- Nhà Cái đến Từ Châu âu

- Site Paris Sportif Retrait Instantané

- Site De Paris Sportifs

- Nouveau Casino En Ligne Francais

- Casino En Ligne

- Nouveau Casino En Ligne Fiable

- Casino En Ligne 2026

- Casino Senza Richiesta Documenti

- Casino En Ligne Qui Paye Vraiment

- Casino En Ligne Fiable

- Casino Bitcoin

- Casino Italiani Non Aams

- Migliori Casino Online Italia

- Siti Non Aams Sicuri

- Casino Non Aams

- Meilleur Site De Casino En Ligne Belgique

- オンラインカジノ

- Meilleur Casino En Ligne France

- Casino En Ligne France

- Casino En Ligne Qui Paye Rapidement

- Casino En Ligne 2026

- Casino En Ligne