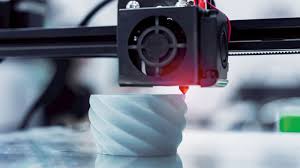

Additive Manufacturing Market is expected to reach $93.36 billion by 2031, at a CAGR of 20.3% from 2024–2031.

The additive manufacturing sector has experienced a significant uptick in utilization, driven by a surge in adoption rates, increased investment in related companies, and growing interest from manufacturers in 3D printing technologies. Industries are increasingly leveraging additive manufacturing to enhance value-added services.

Download Complete Sample PDF Copy Here: https://www.meticulousresearch.com/download-sample-report/cp_id=5838

Key factors propelling this trend include the growing demand for 3D-printed functional end-use parts, advancements in composite 3D printing, the expanding role of 3D printing in regenerative medicine, and rising investments in the aerospace and defense sectors. This article examines the factors contributing to the escalating demand for additive manufacturing and highlights the advantages these technologies offer in optimizing product manufacturing processes across various industries.

Importance of Additive Manufacturing Across Different Sectors

Additive manufacturing, first introduced in the early 1980s, enables the creation of 3D objects using computer-aided design (CAD) files through a variety of technologies. The approach offers numerous advantages, including the consolidation of multiple components into a single part, enhancement of existing part properties, lightweight design capabilities, personalized customization, reduced energy consumption, minimized waste, and lower inventory costs.

The rapid evolution of additive manufacturing has been fueled by a growing number of companies developing printers and offering additive manufacturing services. Notable advancements in this space include:

- November 2023: ADDiTEC (U.S.) introduced two innovative manufacturing platforms, AMDroid and Hybrid3, enhancing precision, efficiency, and versatility in additive manufacturing.

- October 2023: EOS GmbH (Germany) launched the EOS M 300-4 1kW, a cutting-edge additive manufacturing system equipped with one-kilowatt lasers tailored for aluminum and copper 3D-printed applications.

- April 2024: Replique GmbH (Germany) unveiled a 3D printing material hub, featuring over 400 polymer materials sourced from more than 25 material providers.

Emerging Economies and Their Growth Potential

Additive manufacturing is gaining traction in emerging economies such as India, China, and Mexico. Technological advancements and globalization have further popularized this technology in select Asian nations. In China, for example, the automotive industry is utilizing 3D printing to meet the demand for smarter and more efficient production methods. Notably, Pix Moving, an automotive startup based in Guizhou Province, is developing autonomous vehicles by combining 3D printing with generative design techniques. Efforts are also underway in China to preserve and promote its 3D printing culture.

Check complete table of contents with list of table and figures: https://www.meticulousresearch.com/product/additive-manufacturing-market-5838

In India, 3D printing is primarily applied in sectors such as automotive prototyping, tooling, aerospace, defense, medical devices, and jewelry. The burgeoning 3D printing market in India has led to the emergence of local players focused on capturing domestic demand. To accelerate the development of economically viable technologies, the Center of Excellence in Additive Manufacturing under the Ministry of Electronics and Information Technology initiated a business case for digital toys using 3D printing in 2021.

Mexico is quickly positioning itself as a key player in the global manufacturing sector. Its strategic location, skilled workforce, and favorable trade agreements have made it an attractive hub for manufacturing activities. Consequently, many industries are investing in advanced manufacturing technologies, including additive manufacturing, to enhance production capabilities and maintain a competitive edge.

Advancements in Additive Manufacturing Technologies

Recent technological advancements have significantly improved the accuracy and manufacturing capabilities associated with additive manufacturing. Integrating artificial intelligence (AI) into 3D printing processes can yield stronger, more durable products. AI can also enhance the quality of 3D-printed parts by identifying issues early in the process, thereby minimizing manual errors and refining the printing workflow.

AI applications include material assessment prior to 3D printing, as well as the creation of generative 3D designs. For example, AI and machine learning are being incorporated into melt electrowetting 3D printers to produce implants for regenerative medicine. These solutions utilize parameters provided by designers or engineers—such as product size, weight, strength, style, materials, and cost—and leverage cloud computing and machine learning to generate multiple design options.

Startups and research initiatives are actively seeking funding to incorporate AI into 3D printing technologies. In October 2023, Ai Build (U.K.), a 3D printing software developer, secured USD 8.5 million in Series A funding for AI-enhanced 3D printing solutions, backed by notable investors including IQ Capital Partners LLP (U.K.), Nikon Corporation (Japan), ACT Venture Partners (Ireland), Atlas Ventures (U.K.), and Seedcamp (U.K.).

Insights from Additive Manufacturing Market Analysis

Recent insights from Meticulous Research® highlight promising projections for the future of the additive manufacturing market. The sector is anticipated to reach a value of $93.36 billion by 2031, with a remarkable Compound Annual Growth Rate (CAGR) of 20.3% from 2024 to 2031.

As the landscape continues to evolve, North America is expected to maintain a substantial market share in 2024. Key industry players such as Stratasys, Ltd. (U.S.), 3D Systems Corporation (U.S.), EOS GmbH (Germany), Colibrium Additive (U.S.), Materialise NV (Belgium), Desktop Metal, Inc. (U.S.), and HP, Inc. (U.S.) have established a significant presence across various regions, fostering the widespread adoption of additive manufacturing globally. This comprehensive analysis from Meticulous Research provides crucial insights into the additive manufacturing market.

Conclusion

The increasing adoption of additive manufacturing, coupled with heightened funding and interest from manufacturers in 3D printing, has fueled its growth across numerous industries. Furthermore, advancements in technology and supportive government initiatives are enhancing the significance and recognition of additive manufacturing as a pivotal force in the modern industrial landscape.

Buy Now: https://www.meticulousresearch.com/Checkout/86948189

Contact Us:

Meticulous Market Research Pvt. Ltd.

1267 Willis St, Ste 200 Redding,

California, 96001, U.S.

USA: +1-646-781-8004

Europe : +44-203-868-8738

APAC: +91 744-7780008

Email- sales@meticulousresearch.com

Visit Our Website: https://www.meticulousresearch.com/

Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research